| |

Okay, this is a first for me, a completely custom from scratch

job. Above is a very rough mockup of what I think the

finished beast will look like. This one has to be able to

withstand the rigors of the Great Canadian North, so I'll be

filling it with DEET before it leaves the shop. I'm real

excited about this one, since I'm not just rehashing an old cab,

but doing it from the CAD design up. It's made for a

pretty tall guy, so it's got a bit more angle to the monitor

than I would find comfortable, but for him it sould be perfect!

Let's get started! |

|

| |

|

|

|

| |

Parts going

into this one: I'm trying out the brand spankin new Minipac

interface from ultimarc. Also I'll be trying out the

Ultimarc trackball and T-sticks for the first time.

I'm anxious to get the T-sticks, even though they are more

expensive than the Happ sticks I normally use. Also on

this panel will be a genuine Wico 4 way (since microswitch

joysticks never do justice to the old classics) and of course an Oscar

VORTEX spinner. To top it off, visual pinball

buttons.

For the computer, it will

be similar to the killer system in the Zelda mame, complete with

20" monitor and Harmon Kardon or Yamaha Sub-sat system. |

|

|

| |

Here the control panel starts

to take shape. You can see the marked locations of the

controls. I moved the joystick positions up a bit to make

it more comfortable for the player, other than that it's going

to match up with the model. I really need to get a collar for

the router so I can do these holes quicker, but for now the hole

saw does the trick. I'll be putting a order in for the

buttons next week, then to start in on the paint-grade plywood

frame or the top panel. |

|

|

| |

Okay, the panel is

drilled, I'm just fabricating a mounting plate for the

trackball. Now that my mind is back on track I can start

making some progress! I've routed out the joysticks (underside)

and the trackball, and mounted the spinner. I need to

order a few buttons tomorrow. |

|

|

| |

|

|

|

| |

I've had a few e-mails asking

about cabinet finishes. Well this one is going to be a

good example. All the wood is new, so I have to make sure

a good durable finish goes on there. For the best finish,

you just can't beat a good spray gun. For those of you

with access to one, you'll know what I'm talking about.

Otherwise a nice low pile roller will suffice. Lay down a

good primer coat on your piece (don't ever skip the primer!!).

Sand the work and prime again. This is what will allow

your final coat to look good and not just absorb into the wood.

I set the compressor to 40-50psi and load up the gun. For

easy cleanup I use water based latex, but you could get the same

durability in less coats by using oil based or acrylic paint.

Oh and ALWAYS use a good filtration mask when spraying. Here is

the first coat of black on the control panel. I've already

sprayed two coats of primer. I didn't sand too much here

since it will all be covered by the underlay graphic, but

remember that the control panel will take most of the abuse of

things like spills, so make sure it's well sealed. |

|

|

| |

|

|

|

| |

Controls in place, but not

attached. All that remains to do here is mount the

trackball plate, install new t-molding and do up some underlay

graphics. Looking good! |

|

|

| |

|

|

|

| |

The side and back panels are

cut, and I've attached the pieces now with

biscuits and industrial strength glue. As

always I will complete the construction with metal brackets to

make the table bulletproof.

I'm really pleased with

the finish on the wood. It was worth the extra money to

get pre sanded sides. I'll give the whole cabinet a

coat of primer, and then a nice black textured finish to give it

that "from the factory" look. Now to finish the

control panel support and the top. |

|

|

| |

I did a bit more work,

getting the pieces together. I'm going to do a template of

the top so that I can take it in to a local plastics company and

have them do up a nice thick topglass. |

|

|

| |

Here I started in on the

primer. You can see the gold t-molding that arrived today.

Tomorrow I'll try and finish up the primer coat and cut the

groove in the edges and maybe even get on one coat of black. |

|

|

| |

|

|

|

| |

Now we're getting

down to it. The cabinet has a coat of black textured

finish to it, the edge slots are cut and here is a preview of

how the t-molding will look. Now I was quite apprehensive

about ordering the gold, thinking it was going to be tacky, but

I was definitely wrong! This stuff looks great, and is

really heavy duty compared to the regular t-molding. It

even has a protective finish on it that I will peel off when I

deliver it. Now to get to work on the graphic underlay and

the plexiglass top. |

|

|

| |

Now there's a money

shot! I finished up the plexiglass top today! In this

picture the glass overhangs the control panel cutout, but I

ended up doing it flush all the way around. I'm

off now to router the slot for the t-molding around the top and

maybe start planning the monitor shelf so that I can figure out

where the hole needs to be cut. I'll also fabricate some

custom glass clips using bulk steel and a bit of hammering on

the vise. |

|

|

| |

I welded up a custom

bracket for hanging the monitor. I'll do up a reverse

bracket for the bottom and it should be very well secured.

Also this allows for the enclosure to be open, so that I can get

maximum airflow across it with a fan I plan to install on one

side of the cab. |

|

|

| |

Well the support

worked well, but I -assumed- I had it bolted to the frame, but

it turns out the front half was only bolted through some

plastic, so when the full weight of the monitor hung from it,

the electronics and metal pulled away rather violently.

:sigh: Don't think I'll be fixing this 20" monitor with a bit of

glue. I did however, create some new swear words when this

happened, so it wasn't a total waste. Well off to the

monitor store! |

|

|

| |

Okay, one new

monitor and we're back in business.

I tested out the control panel yesterday and it worked without

troubles. I also got the vent holes

on the cabinet drilled. I used the paper template and a punch to set the

pattern, then drilled out the holes. One side will have a

mounted fan. Two smaller templates will be used in the

front for the mounting of the speakers. It's going to be

tight in the enclosure and it'll be a challenge to get those

speakers in there without causing magnetic distortion on the

monitor, or excessive vibration on the motherboard. |

|

|

| |

Due to the angle of

the monitor, I needed to fabricate a custom bezel for the

monitor. Here is the primed piece set in place. I'll

secure it and put on a flat black coat. The underlay

graphic will come flush with the bezel edges for the finished

look. |

|

|

| |

|

|

|

| |

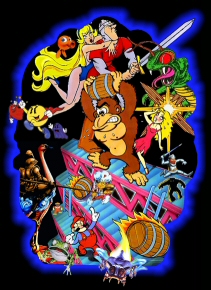

Above is the artwork for the

cab. Since it's going to be a jukebox and arcade

emulator, I did up two pictures. One I found on the net,

which had been put together in illustrator from mostly pictures

from my site (the irony!). The other was a picture from my

buddy Joff who had done up a killer jukebox project with his

class. I'll print them both up at kinko's with a good

laminate coating and get them mounted. While all of this

is going on I welded up four custom brackets. Two go

on the top and attach to clamps inside the cab to keep the top

securely in place. The other two are secured to the

underside of the control panel, and are flat steel welded to

round threaded stock. The threaded steel pokes through

recessed holes in the bottom of the panel, and are secured with

nuts to keep the panel on. Can you tell I love my welder? |

|

| |

|

|

| |

|

|

|

| |

I'm pretty concerned

about heat in this beast, so I had the computer guy bring a

selection of heatsinks for the motherboard. We settled on

a massive sink with a copper/aluminum mix. I've always had

better luck with copper sinks over any other kind, but he swears

by the aluminum, so we found this good compromise. In the

next pic you can see the custom plexiglass mount I made for the

board to keep lots of air movement on it (can't have it cooped

up in a computer case in there!) |

|

|

| |

Now to cram all this

stuff inside the box. Simple, right? right????? |

|

|

| |

I've started the 48

hour burn in period, I want to make sure this puppy will run for

2 days without locking up. The computer guys tell me they

already did a "burn in" test run, but I like to test firsthand

for myself. I'd rather run into problems here than when

it's hundreds of miles away! I also returned the Yamaha

speakers and got a Creative Labs set instead. A few fellow

cab builders said the sound was phenomenal on these speakers,

and more importantly, they come with a volume control on a wire!

I can mount that under the control panel and he doesn't need to

crack it open to turn down the volume. It's still going to

be tight in there with the sub. I can honestly say, the Creative

system rocks! The monitor here has a forward tilt to it.

You might think it's not enough until you see the height on the

new owner, I think he's a retired basketball player or

something. :) |

|

| |

Here is a snap of

the panel graphic and the sideart in place. Notice also

the pinball flipper and 'tilt' buttons. Lookin

good! |

|

|

| |

Menu screen ready to go! |

|

|

| |

A nice shot of the

completed control panel. |

|

|

| |

Turn the lights down and

let's see what this puppy can do. Off to play a few games

and maybe a bit of pinball before I get it ready for delivery! |

|

|

| |

A dark room shot

with the sound activated light tube and the coin windows.

Bling. |

|

|

| |

Here is a nice pic of lake

Huron where this cabinet has taken up residence. I wasn't

joking about it being at a cottage! |

|

|

| |

There she be. There's

got to be something said for a game of Galaga nestled into the

peaceful setting of Canadian cottage country. This

place is the ultimate dedication to arrested development.

Game on! |

|

|

| |

BACK

|

|